The series of HY2212 is created for a single-cell lithium-ion or can also be used for multi-cell battery packs with individual cells. This IC is capable of active balancing of a cell by electrical level monitoring and it comprises a very high-accuracy voltage detection circuit and delay circuit. The capacitor and resistor are essential for suppressing the ripples and disturbance from the charger.Ĭoming to the cell balancer circuit, the heart of this circuit is HY2212 BB3A, 1 cell Li-ion/polymer battery charger balance IC. In the above figure, you can observe that the VSS pin is connected to the positive terminal of the cell with a resistor R24 and VSS and VDD have a capacitor C1 parallel to them. An explanation of overcurrent is given later in this article. the short circuit is inhibited by turning off the discharge control MOSFET. In the case of a short circuit the voltage exceeds V SIP, and the fault, i.e. The DW01-A constantly monitors the overcurrent or short-circuit by measuring the voltage at the current sense pin.

The IC measures the voltage of the cell using an internal voltage divider circuit between V CC and ground pin and based on the electrical characteristics table shown above control the Over-discharge (OD) and Overcharge (OC) pin thus controlling the transistors Q2 and Q3 in the figure below. Here, the Batt+ and S3 denote the positive and negative terminals of the cell respectively. The protection circuit of this battery pack is shown here.

The working of any Integrated circuit depends on how it has been designed, which is given by the manufacturer, the electrical characteristics of DW01 is given in the table below: The short circuit and overcurrent are detected by the comparators which compare the voltage between CS pin input and VSS. It has an internal voltage divider circuit that is responsible for measuring the undervoltage and overvoltage of the cell. You can refer to the IC’s datasheet to see the functional diagram and other data. Each individual cell has 1 DW01-A connected which monitors the health of the particular cell. It is responsible for all the protection features of the BMS. The figure below shows the parts of BMS responsible for different operations.įrom the above image, it is clear that one IC is responsible for overvoltage, overcurrent, and short circuit protection and that IC is DW01-A, whereas another IC BB3A is responsible for the cell balancing.ĭW01-A is a 1 cell Li-ion/ Polymer battery protection IC. But all the ICs will have the same pinouts and functioning. The BMS has 2 ICs, DW01, and BB3A some variants of this BMS may have the same ICs or similar ICs from different manufacturers. The BMS acts like 4 separate modules for 4 separate cells and then these 4 modules are very smartly integrated together with transistors and passive components to make a complete BMS that is able to deliver current up to 40A and protect individual cell’s parameters. Positive Terminal Connection for the battery pack for charging and connecting the load Negative Terminal Connection for the battery pack for charging and connecting the load. The image below shows how we need to connect the cell with BMS. It is proved and validated that the side cooling topology with a 5 m/s air velocity and a 5 mm spacing between cells is the optimum design.The BMS module has a neat layout with markings for connecting the BMS with different points in the battery pack. The simulation results are validated with experimental results showing an acceptable error of less than 2 ☌. Then, different operating and design parameters including inlet air speed, inter-cell spacing, and the airflow direction are studied comprehensively. Pertaining to the versatility of the detailed model, an air-cooled thermal management system is designed considering different topologies.

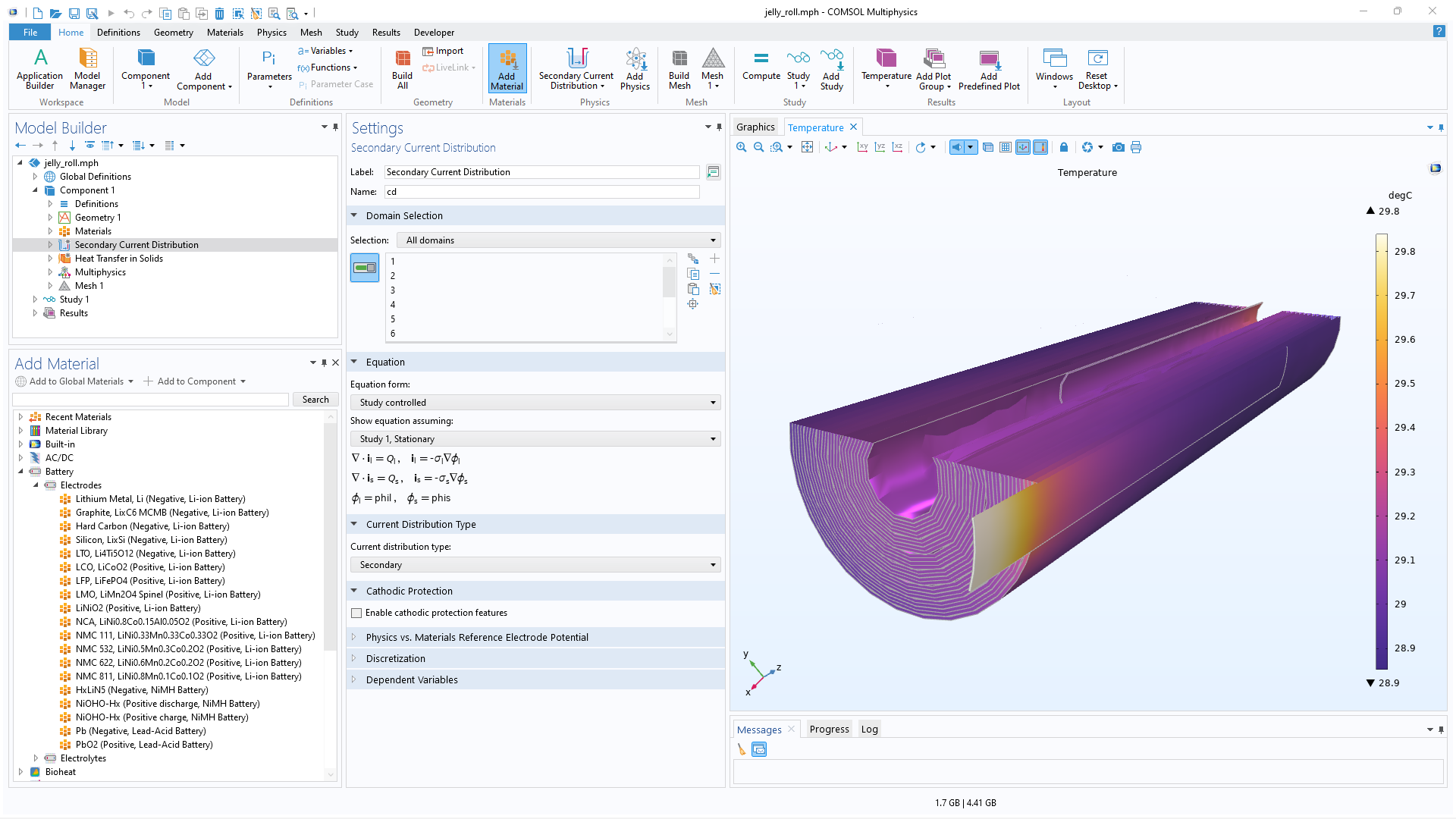

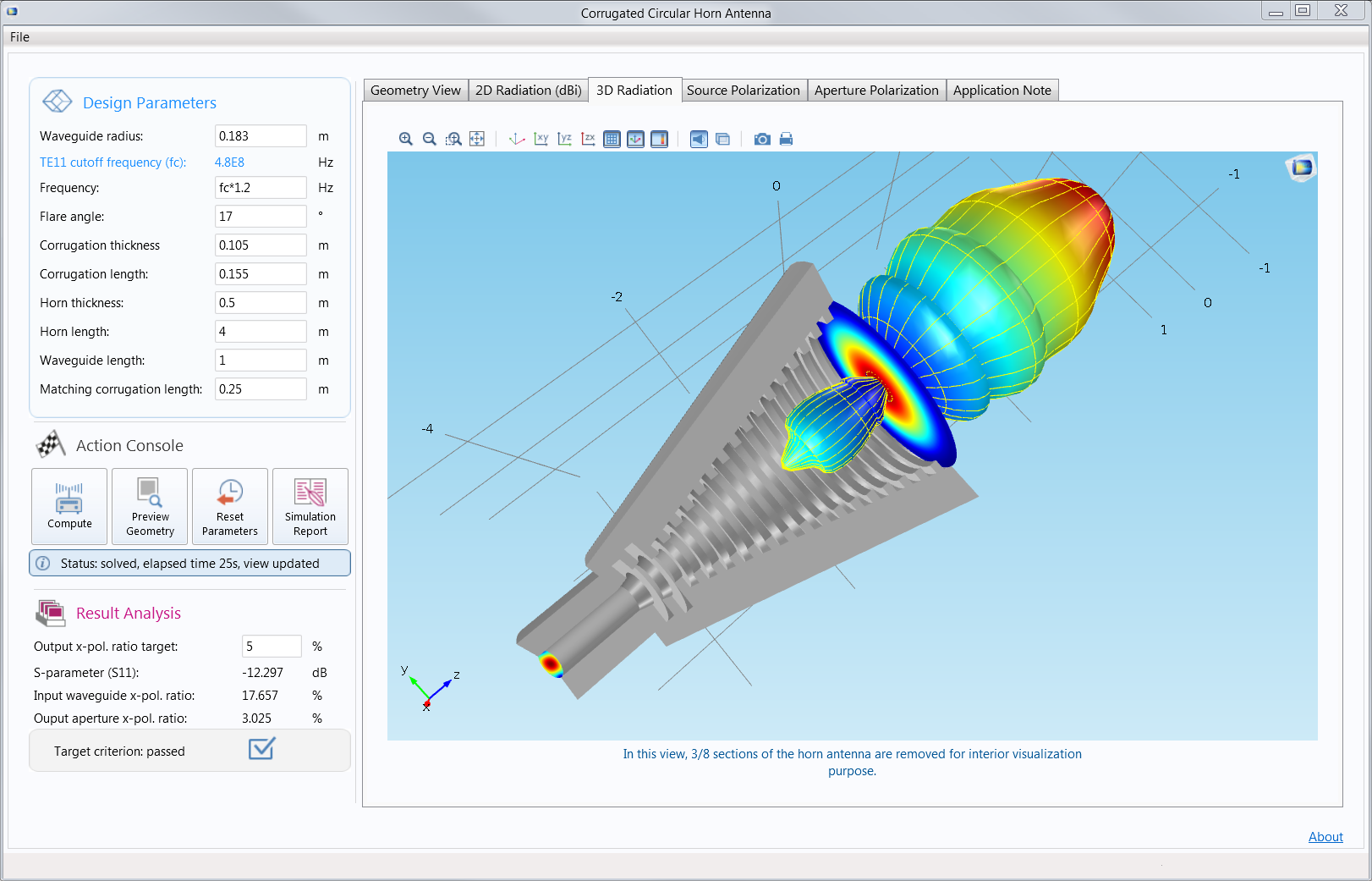

#Comsol 5.1 lithium ion battery module software

In this study, a detailed three-dimensional thermal model is developed in COMSOL Multiphysics software at cell and module level. Nonetheless, in order to design a proper thermal management system, dedicated thermal modelling development is an essential task. However, for this kind of applications, a thermal management system is crucial to ensure thermal stability and a long lifespan. Lithium-ion capacitor (LiC) has emerged as a promising technology for high power applications due to the solution offered by its power density, higher-voltage operation than super-capacitor (SC), and their excellent durability (more than 2 million cycles).

0 kommentar(er)

0 kommentar(er)